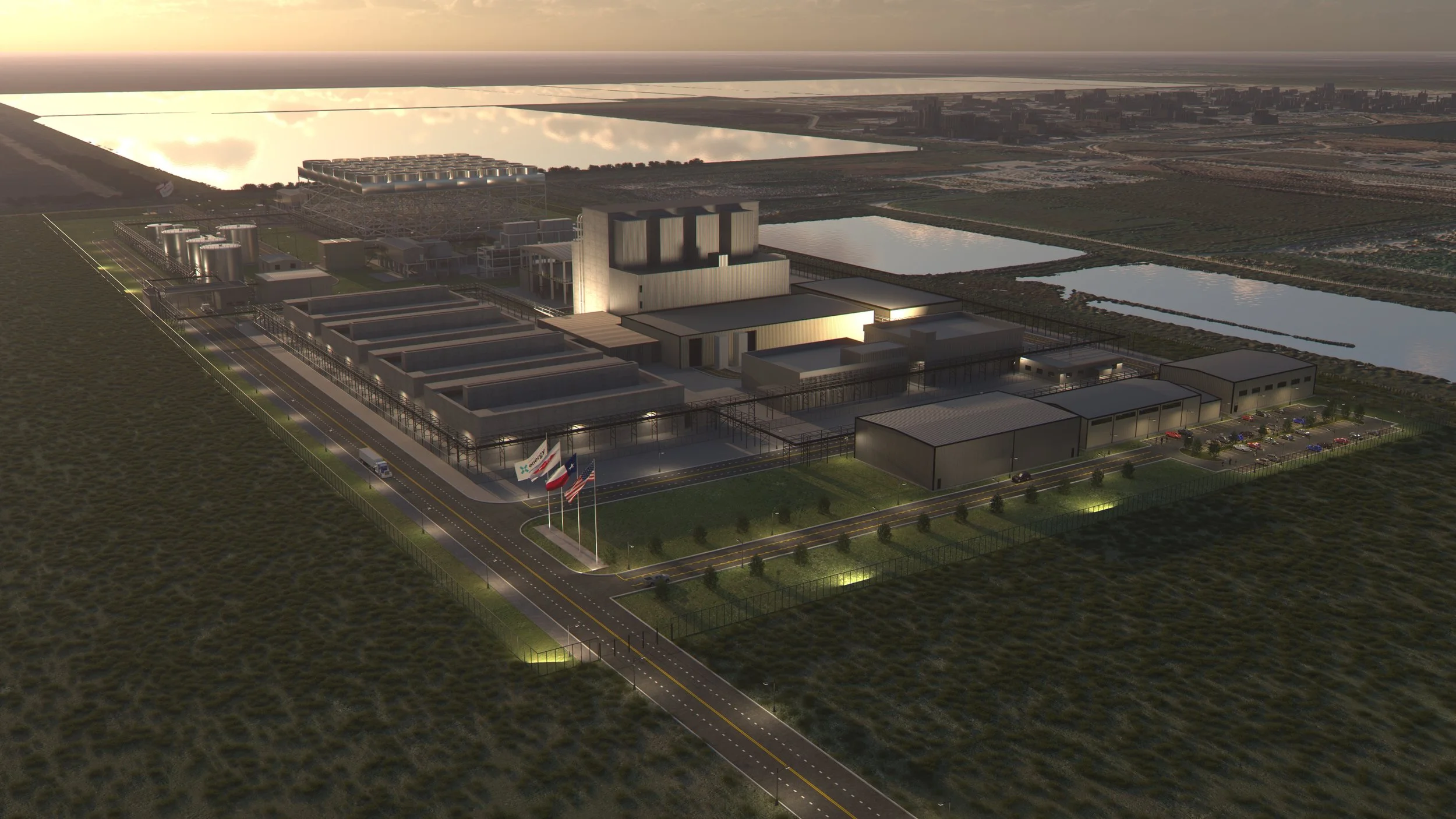

Advanced Nuclear Reactor Project in Seadrift, Texas

Project Overview | Milestones | FAQ | Contact Us

Dow and X-energy are partnering for the initial deployment of X-energy’s Xe-100 advanced reactor at Dow’s UCC Seadrift Operations manufacturing site on the Texas Gulf Coast. Once complete, Long Mott Generating Station is expected to be the first grid-scale advanced nuclear reactor deployed to serve an industrial site in North America.

The four-unit plant is expected to provide the Seadrift Site with safe, reliable, clean electricity and steam to reduce the Seadrift Site's Scope 1 and 2 emissions by approximately 500,000 MT CO2e/year and ensure the site remains competitively advantaged. The proposed project could begin construction later this decade and start up early next decade.

Dow’s UCC Seadrift Operations is the second largest Dow facility in Texas, spanning about 4,700 acres and employing more than 1,200 people. The products made at Seadrift are used to make consumer products used every day in homes, schools, offices, hospitals, vehicles and by other industries, producing more than 4 billion pounds of materials per year across a wide variety of applications including food packaging and preservation, footwear, wire and cable insulation, solar cell membranes, and packaging for medical and pharmaceutical products.

The project is being developed by Dow’s wholly-owned subsidiary, Long Mott Energy LLC, and is focused on providing the site with safe, reliable, and clean power and industrial steam replacing existing energy and steam assets that are near end-of-life. The project is supported by the U.S. Department of Energy’s Advanced Reactor Demonstration Program which is designed to accelerate the deployment of advanced reactors through cost-shared partnerships with U.S. industry.

Why Nuclear?

Nuclear is the only energy source that can provide consistent, reliable, and scalable clean power and heat. X-energy’s proven technology offers one of the most cost-effective and safest ways to bring net-new carbon-free energy to market. Here’s why more and more companies are choosing nuclear energy.

Clean

Nuclear provides clean, always-on energy. X-energy’s Xe-100 small modular reactor is uniquely suited to provide all power needs to the Seadrift Site, with a smaller operating and environmental footprint.

Reliable

Nuclear’s reliability and resilience is one of its most important attributes, and our continuous fuel cycle design allows the Xe-100 to reliably operate at a 95% capacity factor, significantly higher than other generating sources.

Safe

X-energy’s technology uses TRISO fuel, often referred to as, “the most robust nuclear fuel on earth.” The Xe-100's design pairs our proprietary TRISO-X fuel will intrinsic safety, using both physics and mechanical systems, to provide safe, continuous operation.

Versatile

X-energy plants are designed to be configured to deliver both power and high temperature heat at 565°C, providing an emission-free, always-on solution for industries such as mining, chemical production, and petroleum refining and other industrial processes.

“Dow is driving the adoption of technologies essential to decarbonizing hard-to-abate industrial applications to offer low carbon products to our customers. This advanced nuclear project builds upon Dow’s previous success in reducing the carbon emissions intensity of our manufacturing fleet and advances our path toward carbon neutrality by 2050.”

Jim Fitterling

Chairman and CEO Dow

“X-energy will deliver our innovative technology to the Texas Gulf Coast to efficiently and reliably decarbonize the Seadrift Site’s heat and power assets. We will showcase the unique versatility and wide range of applications of the Xe-100 advanced small modular nuclear reactor for energy production and manufacturing.”

J. Clay Sell

CEO X-energy

Milestones

2025

NRC Publishes 18-Month Review Schedule for Xe-100 Construction Permit Application

In June 2025, the NRC announced an 18-month timeline to complete environmental and safety reviews for Dow and X-energy’s Xe-100 Construction Permit Application. Citing the application’s quality and effective pre-application engagement, the NRC will review the Texas Gulf Coast project and conduct its environmental assessment concurrently.

TRISO-X Allocated First Tranche of HALEU for Fuel Fabrication

In April 2025, TRISO-X was allocated an initial tranche of High-Assay Low-Enriched Uranium (HALEU) through the DOE’s HALEU Availability Program. This commitment supports X-energy’s role in the Advanced Reactor Demonstration Program and will be used to manufacture fuel for the first core loads at Long Mott Generating Station on the Texas Gulf Coast.

Dow and X-energy Submit Construction Permit Application

In March 2025, Long Mott Energy, LLC submitted a construction permit application to the NRC for the first Xe-100 deployment. Since 2018, X-energy has worked closely with the NRC through pre-application, highlighting the Xe-100’s advanced safety features, including its innovative fuel design and passive systems.

2024

X-energy Selects Geiger Brothers for $40.8 Million Site Development Phase of TRISO-X Fuel Fabrication Plant

In December, TRISO-X, a subsidiary of X-energy, chose Geiger Brothers, Inc. to complete site development for its pioneering advanced nuclear fuel fabrication facility, TX-1, in Oak Ridge, Tennessee. As part of the Advanced Reactor Demonstration Program, TX-1 will supply fuel for the Xe-100’s initial deployment at Dow’s Seadrift site as well as future deployments.

X-energy Unveils Plant Support Center for Training Xe-100 Advanced Small Modular Reactor Operators

In March 2024, X-energy launched the Plant Support Center (PSC), the first training facility for Xe-100 reactor operators. This 10,000 sq. ft. center features a full-scale control room simulator, Reactor Protection System prototype, virtual reality experiences, and classrooms.

2023

Dow’s Seadrift Site to Host X-energy SMR Project for Safe, Zero-Emission Power and Steam

In May 2023, Dow announced its UCC Seadrift Operations site in Texas as the location for its advanced small modular reactor project with X-energy. The initiative aims to deliver safe, reliable, zero-carbon power and steam. The 4,700-acre Seadrift facility produces over 4 million pounds annually of materials used in everyday items such as food packaging, footwear, wire insulation, solar membranes, and medical packaging.

Dow, X-energy Sign Joint Development Agreement

In March 2023, Dow and X-energy signed a joint development agreement to build a four-unit Xe-100 facility at a Dow Gulf Coast site. The agreement covers up to $50 million in engineering work, funded on a 50/50 cost share by Dow and the Advanced Reactor Demonstration Program. It also includes preparing and submitting a Construction Permit application to the NRC.

2022

Dow And X-energy to Deploy Advanced SMR for Carbon-Free Power

In August 2022, Dow and X-energy announced a letter of intent to support Dow’s carbon emissions reduction goals by deploying X-energy’s Xe-100 high-temperature gas reactor at a Dow Gulf Coast site. The reactor will deliver cost-effective, carbon-free heat and power. Dow also committed to a minority equity stake in X-energy to advance small modular nuclear technology.

2021

X-energy Signs ARDP Cooperative Agreement

In March 2021, X-energy signed the DOE’s ARDP Cooperative Agreement, marking the start of its partnership with the Department of Energy. The program provided $80 million in initial funding, with a total DOE investment of about $1.23 billion over the project’s duration.

2020

X-energy Awarded $80 Million for the Department of Energy’s Advanced Reactor Demonstration Program (ARDP)

In October 2020, the U.S. Department of Energy named X-energy one of two awardees in its Advanced Reactor Demonstration Program (ARDP). X-energy received $80 million in initial funding to develop a commercial four-unit Xe-100 nuclear plant and a full-scale TRISO fuel fabrication facility.

Frequently Asked Questions

-

Once operational, Seadrift will be the first manufacturing facility in the world to be powered entirely by clean, reliable nuclear energy. Unlike smaller demonstration projects, X-energy’s projects are paving the way for commercial-scale advanced reactors for large industrial Applications.

-

Each of X-energy's Xe-100 advanced small modular reactor provides 80 MW of electric power per reactor. Dow and X-energy plan to install four reactors at the Seadrift Site to produce 320 MW across the plant.

X-energy’s technology is a unique fit for industrial use because of its high-temperature steam output.

The plant is expected to continuously supply electric power and steam to all operations of the Seadrift Site.

-

Construction on the four-reactor project is expected to begin in the coming years, with potential startup early next decade. Timely approval of the construction permit from the NRC will be an important step forward on the project.

-

The Seadrift site is an important manufacturing site for current and future products, where Dow saw the opportunity to replace end-of-life assets with safe, reliable, lower carbon emissions technology.

Dow selected the Seadrift Site because it is an important manufacturing site for current and future products. With additional growth coming to the site and existing energy and steam assets nearing their end-of-life, we saw the opportunity to replace end-of-life assets with safe, reliable, lower carbon emissions technology.

Nuclear technologies have strong support in Texas due to surging demand for reliable energy and the economic opportunities the industry can bring to the state. -

The ARDP is designed to help domestic private industry demonstrate advanced nuclear reactors in the U.S.

The U.S. Congress and the DOE have acknowledged that advanced nuclear energy systems hold enormous potential to lower emissions, create new jobs and build a strong economy. More information can be found here: Advanced Reactor Demonstration Program | Department of Energy.

Technology

-

The Xe-100 is designed to run on a continuous cycle and operate at temperatures of 750 degrees C, maximizing the energy extracted from every atom. Helium is cycled through the core absorbing heat without becoming radioactive. The heated helium is then used to boil water into steam that turns a steam turbine to generate always-on, carbon-free electricity. By using a helium coolant as compared to water, the Xe-100 is designed to deliver heat at higher temperatures (750°C helium outlet temperature and 565°C steam from the steam generator) than conventional reactors, providing a clean solution for various use cases, including power generation and process heat for critical industrial applications, like at Dow’s facility.

X-energy's nuclear technology represents the next generation of clean, safe, reliable, and zero-carbon nuclear energy. -

Our technology is among the safest clean energy technologies, built on decades of proven high-temperature gas-cooled reactor (“HTGR”) operating experience. X-energy’s pioneering Xe-100 advanced small modular reactor and TRISO-X fuel are designed not to melt.

TRISO-X fuels are a proven, safe technology, first developed more than 60 years ago, with the modern TRISO-X particle evolving through a series of improvements in particle design, coating layer properties, and kernel composition. Retaining the fission products within the fuel without requiring complex safety systems helps engineers to simplify reactor design, which should reduce licensing complexity and simplify operations.

-

The unique design of X-energy's fuel lends itself to a simpler, more manageable, and safer approach to spent nuclear fuel management. TRISO fuel is differentiated in that:

The fuel acts as a moderator for nuclear fission.

The pebble retains the fission products produced during operations.

Pebbles act as their own permanent waste containment vessel and can be directly transferred to dry storage without need for a spent fuel pool.

-

Our innovative fuel technology combines a higher heat tolerance with lower power density to unlock the widest range of use cases in the industry, allowing industrial partners such as Dow to leverage nuclear energy to power their processes. The high temperature output of the Xe-100 can be used to supply process heat or electricity to conventional processes without generating any greenhouse gases. For the Xe-100, helium gas is cycled the through the core to absorb heat generated through nuclear fission.

The Xe-100 offers several additional benefits over large reactors. Our designs are more cost-effective and faster to build, and the modularity of our designs means our reactor is smaller than legacy light water reactors (LWRs) and easier to deploy while offering a condensed timeline deployment in comparison with LWRs.

Our leading position in commercializing SMR technology – from our longstanding partnership with Dow to the recently-announced project in Washington with Amazon and Energy Northwest – further sets X-energy’s technology apart from competitors.

-

Yes. The technology will meet all required safety standards and regulatory requirements as well as Dow's hallmark operations, environmental, and product safety standards. And we would work to educate stakeholders throughout the process on all aspects of this technology (safety; sustainability; scalability; etc.). According to X-energy, the Xe-100's low reactor power density and self-regulating core design mean that if cooling stops, reactions in the core naturally shut down. As a result, the plans are designed to be "meltdown proof" under foreseeable adverse conditions and require no operator actions under such adverse conditions – it's the laws of physics, beyond mechanical systems, that ensure safety. According to X-energy, the TRISO-X fuel is intrinsically safe as it cannot get hot enough to melt in any anticipated operating scenario. A major reason for this is that the fuel itself is a containment vessel, as it is coated in several layers of carbon and silicon. According to the Nuclear Energy Institute, America's 92 nuclear power plants are among the safest and most secure industrial facilities in the world, with oversight by a dedicated regulatory body, the Nuclear Regulatory Commission (NRC)

Impact

-

Yes. Approximately 1,000 construction jobs will be supported at peak construction as the new facility is constructed. Up to 100 new, permanent jobs could be required to operate and maintain the facility.

-

The advanced nuclear project is expected to reduce the Seadrift Site's emissions by approximately 500,000 MT CO2e/year. The advanced nuclear assets will replace the site's existing gas-fired and steam turbines.

-

X-energy and Dow have been engaged in extensive pre-application activities with the NRC to ensure the environmental considerations of the project align with NRC expectations. By deploying Xe-100 reactors, the Seadrift site will reduce emissions by replacing traditional fuels with clean, reliable, safe power.

The site has been carefully planned to minimize the water requirements and physical footprint of the facility and ensure no impacts to endangered species or historical or cultural sites.

-

We have identified several options adjacent to existing facilities on Dow land. However, further assessment and analysis are required to select an exact location. The nuclear assets will sit on approximately 30 acres of the 4,700 acres of Dow land.

-

Consistent with U.S. regulatory requirements, the spent fuel goes directly into a canister, where it remains until placed in a final repository. It does not need to cool in water, as is the case with traditional nuclear fuel.

The Xe-100 plant is designed to store all spent fuel for the entire 60-year operational life in one designated spent fuel storage building per reactor.

As is the case today with all commercial spent nuclear fuel, plant owners are responsible for the management of the fuel as it leaves each reactor, and the U.S. Department of Energy has the final legal responsibility to take title to the fuel, and for final disposal in a geologic repository under the Nuclear Waste Policy Act, as amended.

-

Dow and X-energy will work very closely with regulatory agencies to ensure that all safety precautions and protocols are followed.

Safety is supported through operators, who will be licensed by the Nuclear Regulatory Commission (NRC), as well as utilizing detailed operating procedures. In addition, every plant creates and maintains emergency response plans that are approved by both the NRC and the Federal Emergency Management Agency (FEMA).

Nuclear power plants must be designed and constructed to meet rigorous safety requirements imposed and enforced by the NRC. The NRC will review plant qualifications, plans, and procedures in the course of plant licensing.

Safety is the highest priority of X-energy and the U.S. nuclear industry. We will demand the same level of meticulous regard safety and safe operations as we exhibit at all of our existing chemical facilities. The site will be designed to handle extreme weather events that may impact plant operations, including hurricanes.

The Xe-100's Reactor Protection System is designed to automatically shut the plant down in the event of a flood, or any event that results in a loss of offsite electricity.

-

The transportation of nuclear and radioactive materials is strictly regulated by the U.S. Department of Transportation (DOT) and Nuclear Regulatory Commission (NRC).

X-energy will ship its TRISO-X nuclear fuel in penetration-hardened, regulator-approved packages on existing highways using semi-trailers, just as other nuclear fuels have been safely transported for many decades.

The NRC has licensed and certified X-energy's nuclear transport package to handle HALEU and TRISO-particle bearing pebbles.The Certificate of Compliance for the TRISO-X transport containers is publicly available on the NRC website and explains the rigorous testing of nuclear fuel shipment packages with regard to mechanical integrity, fire protection, and penetration resistance.