The unprecedented growth of artificial intelligence represents both a technological revolution and an energy challenge of historic proportions. AI has transformed everyday life in just a few short years. But as the computing needs of AI increase exponentially, so too does the energy required to power the data centers that are the backbone of this new technology. Traditional power solutions are struggling to keep pace with AI's need for reliable, continuous energy. In this new era of power demand, hyperscalers like Amazon are turning to nuclear to meet the moment.

X-energy's Xe-100 advanced nuclear reactors offer a solution uniquely suited to power AI infrastructure: clean, reliable power that operates 24/7 with minimal land use and maximum output stability. Our partnership with Amazon aims to add 5 GW of new nuclear by 2039, offering a roadmap for how next-generation nuclear technology can enable next-generation computing at scale.

AI Power Usage: A New Challenge for our Electric Grid

The era of flat power demand is over. For those that follow energy closely, the AI revolution is a generational shift in how we bring new power generation to the grid. According to Grid Strategies, U.S. electricity demand is projected to surge by 15.8% (128 GW) by 2029, a five-fold increase in load growth forecasts from just two years prior. This unprecedented growth is largely driven by data centers supporting AI workloads, with demand concentrated in specific regions like Northern Virginia, Texas, and Georgia. We're witnessing annual load growth rates of 3%, levels not seen since in decades. While manufacturing and electrification contribute to this trend, data centers represent the single largest component of new demand, creating concentrated pockets of intensive energy requirements that challenge traditional grid planning and financing models.

How Much Power Does AI Use?

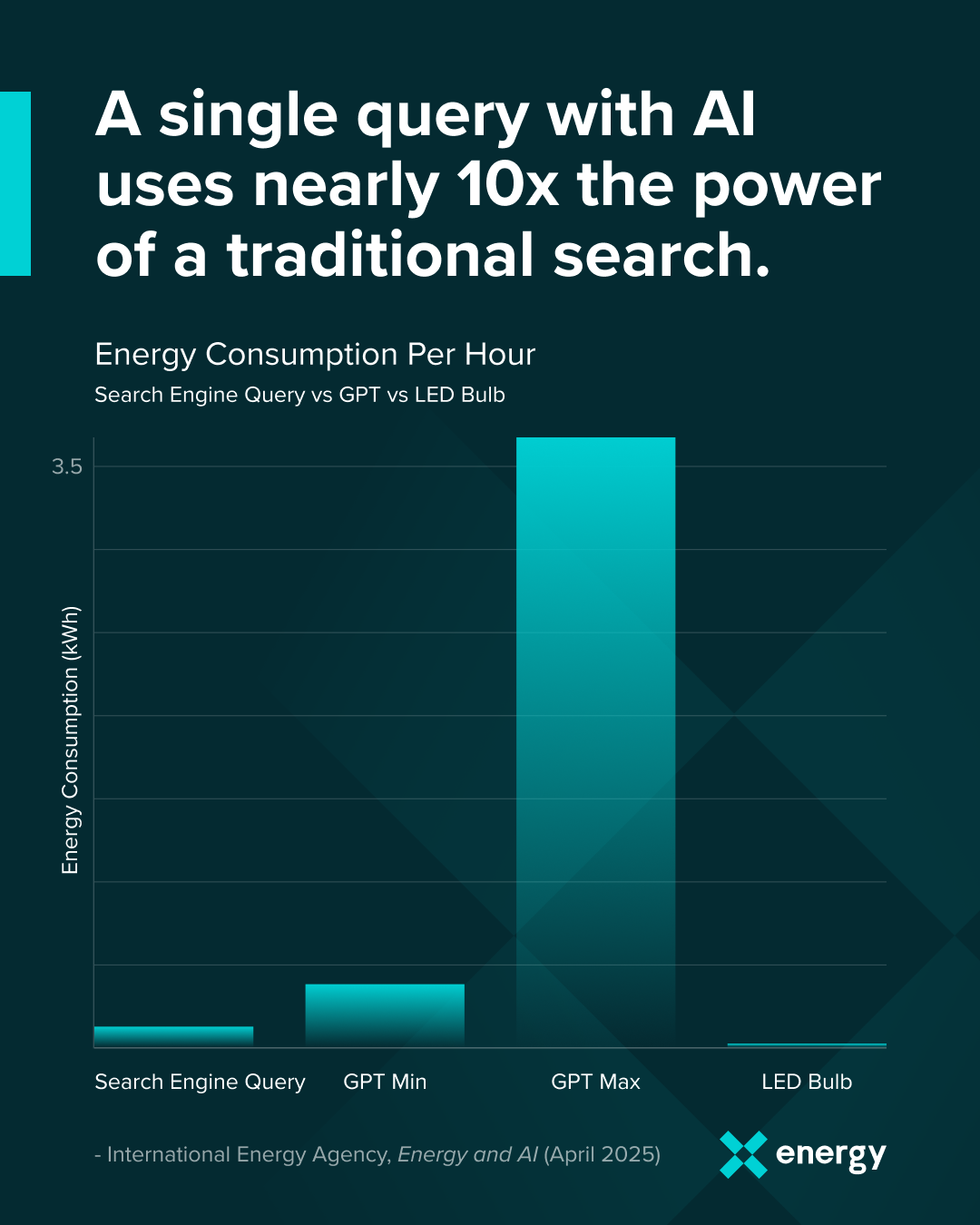

The power demands of artificial intelligence have grown exponentially as models increase in complexity, and more and more consumers use AI in their daily life. According to the International Energy Agency (IEA), data centers already consume approximately 1-1.5% of global electricity, with AI applications driving a significant portion of this demand. The IEA estimates that a single AI query requires about 2.9 watt-hours of electricity, roughly ten times the energy used by a standard web search (0.3 Wh).

At scale, these requirements create substantial demand. Goldman Sachs research indicates that global data center electricity consumption could grow by over 165% by 2030. In the United States alone, Wood Mackenzie projects demand growth ranging from 13 to 55 GW over the next 5 years. In the long-term, the critical question isn't how much power AI uses today, but how much it will require tomorrow, and how fast we can deploy new generation to meet that demand.

Advanced Nuclear: An Ideal Match for AI Power Usage

Powering AI requires energy sources that are reliable, scalable, and sustainable. Advanced nuclear power offers a unique solution to this challenge. According to the Nuclear Energy Institute, nuclear power plants maintain the highest capacity factors of any energy source, operating at full power more than 93% of the time, making them ideally suited for data centers that cannot afford downtime.

Beyond reliability, nuclear energy's remarkable energy density provides significant advantages for powering AI infrastructure. A single X-energy Xe-100 reactor can generate 80 megawatts of electricity from a minimal land footprint and flexible siting compared to traditional large reactors, allowing for deployment near data center facilities without the sprawling land requirements of wind or solar installations. This proximity reduces transmission losses and enhances grid stability, critical factors for hyperscalers like Amazon operating massive data center facilities that require consistent, high-quality power.

The Xe-100: The Solution to AI Power Consumption

X-energy's Xe-100 represents a new era in nuclear reactor design well-aligned with the demands of modern AI infrastructure. This 80MWe high-temperature gas-cooled reactor (HTGR) delivers unparalleled reliability while maintaining the highest safety standards in the industry. Unlike conventional nuclear plants, the Xe-100 leverages a modular architecture that allows for phased deployment in multi-packs, enabling precise load-following to meet data center power requirements as they scale.

The Xe-100's unique design uses helium gas coolant and TRISO fuel, described by the Department of Energy as "the most robust nuclear fuel in the world." X-energy’s technology is built on decades of operational research and expertise on these technologies, improving upon them to create an intrinsically safe design where safety is ensured through fundamental physics rather than complex mechanical systems. For AI data center operators, this translates to exceptional reliability with safety built-in from the ground up.

Amazon and X-energy: A New Model for Power Deployment

The energy challenges created by AI's growth demands innovative solutions beyond traditional power purchase agreements and paths to market. Amazon chose to meet this challenge head-on through direct equity investment in X-energy, putting substantial capital to work immediately to advance our advanced nuclear technology development. This strategic partnership represents a fundamental shift in how energy-intensive companies approach power procurement, moving from simple customer relationships to becoming active stakeholders in emerging energy technology.

Amazon's investment helps accelerate the development of our manufacturing capacity to support over five gigawatts of new nuclear energy projects, beginning with the Energy Northwest collaboration to deploy twelve Xe-100 units at Columbia Generating Station. This ambitious commitment demonstrates Amazon's understanding that powering AI's future requires not just buying clean energy, but actively building the infrastructure that will enable continued technological progress while meeting climate goals, and ensure our economic growth is never constrained by energy.